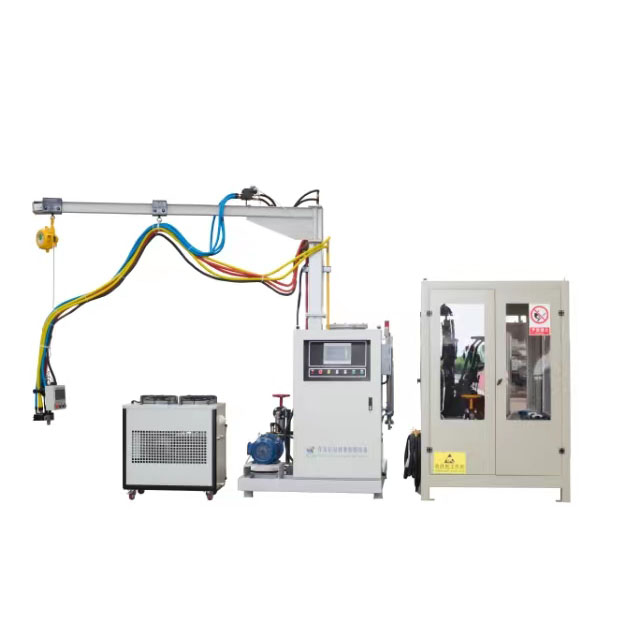

Water Tank Environmental Protection Cyclopentane High Pressure Foaming Machine

Water tank environmental protection cyclopentane high pressure foaming machine

Description

Cyclopentane High Pressure Foaming Machine

The cyclopentane foaming machine is a new type of rigid polyurethane foam foaming machine, which is used to replace chlorofluorocarbons (CFCS) that have damage to the atmospheric ozone layer. It has been widely used in the production of fluorine-free refrigerators, freezers, cold storage, pipeline insulation and other fields. Fluorine-free foaming and cyclopentane safety detection, alarm and treatment system makes the use of cyclopentane foaming machine more safe and reliable. With the expiration of ODS prohibition in Monterey and other conventions approaching, CFCr and HCFCs products will soon be banned. Cyclopentane will become the leading role in the field of polyurethane foaming agent, so cyclopentane foaming machine will be selected by all industries. Meet the market demand, comply with the trend of environmental protection.

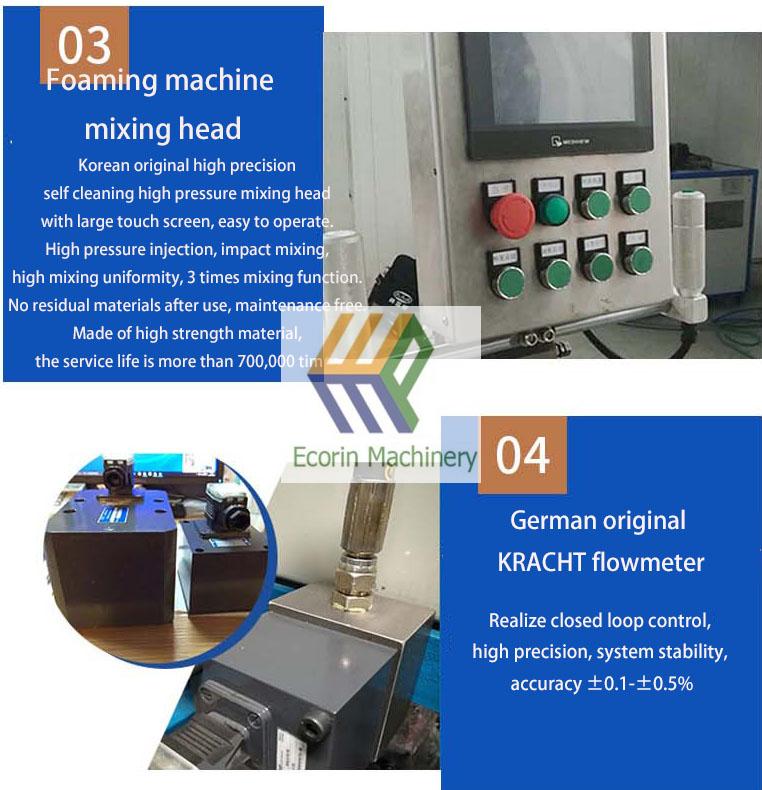

With Siemens PLC+ double frequency conversion multifunctional safety device, 38 intelligent self-check protection points, independent anti-static room, automatic identification system of alkane gas concentration level, automatic 2-3 level air extraction system, Siemens explosion-proof motor, independent ground guide device, gun lead electrostatic export device, external 2 groups of independent comparison constant temperature, 12~100 kinds of irrigation timing quantitative control, Shooting temperature lock, fault self-check alarm, etc., this system uses self-cleaning/anti-reverse/anti-splash/new V-shaped foam gun (to achieve 3 times mixing function), beautiful structure, easy to operate. According to the actual situation of customers, it can also be used with one machine and two guns, two guns can be switched automatically, frequency conversion and energy saving, and it can be used freely, specially tailored for customers to improve the foaming system.

Multi-modular design, improve operability, improve the use of stability, accurate filling, reduce the use of energy consumption, automatic balance, automatic adjustment of the amount of material, intelligent compensation, to meet various fields of product production and use customization.

Cyclopentane Foaming Machine Parameters

| Item Model | HW(R)-20 | HW(R)-40 | HW(R)-100 | HW(R)-200 | |

| Injection volume(g/s) | 30-300(g/s) | 60-600(g/s) | 130-1600(g/s) | 250-3000(g/s) | |

| Mixing head type | HL-0710 | HL-1014 | HL-1218 | HL-1625 | |

| Rated Power (KW) | 18KW | 23KW | 32KW | 55KW | |

| Metering pump type | 6 | 12 | 28 | 55 | |

| Air source | 0.6mpa (Nitrogen optimum) | ||||

| Injection time precision | 0.1s-99.99s | A:B Injection ratio | 1:3-3:1 | ||

| Host-driven mode | Explosion-proof motor + magnetic link + polyurethane special pump | Material transfer mode | Pneumatic diaphragm feeding system | ||

| Feedstock injection pressure | 8-15mpa | Injection repetition precision | ≤1% | ||

| Temperature control precision | ±2% | Working pressure of hydraulic station | 12-20mpa | ||

Product Details

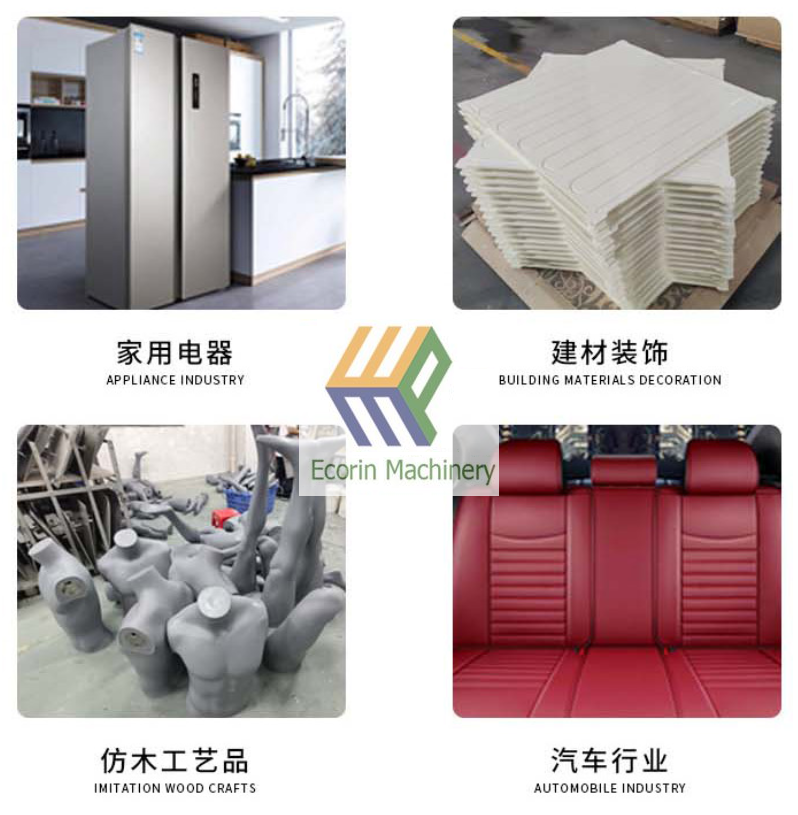

Use of Cyclopentane Foaming Machine

It is widely used in the production of fluorine-free refrigerators, freezers, freezers, thermal insulation barrels, thermal insulation boxes, water heaters, water dispensers, ice machines, vending machines, ice cream machines and cold storage, pipeline insulation and other fields.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Chen

Phone: +86 15806428103

E-mail: info@ecorinpufoaming.com

Whatsapp:+86 15806428103

Add: Liaoning Road, Beiguan Industrial Park, Jiaozhou, Qingdao Shandong Province