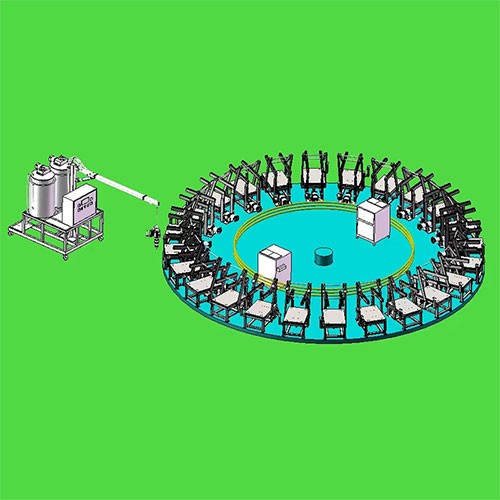

Disc Polyurethane Foaming Production Line

Disc Polyurethane Foaming Production Line, Polyurethane Foaming Production Machine

Description

This assembly line is of round table structure, and the frame of the turntable is all 100*100*4 square tubes divided into 18 equal parts. The diameter of the working table is 12 meters, and the effective working length of the epitaxial table is about 37 meters. The mold is placed on the turntable table with 5mm steel plate.

1. The workbench is about 500mm away from the ground. The electric cabinet placed on the rotary table can be remotely controlled to run the rotary table.

2. In the center of the rotary plate is the rotary transmission device (collector ring four-core 380V) and the rotary gas joint. The collector ring provides the power demand for the mold temperature machine, and the rotary gas joint provides the compressed air source. (If not used for the time being, it can also be reserved for increasing automation in the future.)

3. There are three ring pipes 4 meters away from the outer edge of the disc (that is, the diameter of the circular waterway is 4 meters). The lower two ring pipes are connected with the inlet and outlet of the mold temperature machine, and the upper channel is connected with the rotary gas joint, indicating that the water pipe material is PPR pipe.

4. The annular piping outside the mold temperature machine is provided with a multi-channel interface, which can be connected with the mold in series and parallel at will.

5. The rotary table is equipped with a circle of ground rail, to support the weight of the whole rotary table and can rotate smoothly. The power of the rotary table is provided by two 1.5kw1:100 reduction motors. The rotating speed of the table is controlled by the frequency converter. The rotating speed of the table can be set arbitrarily. The rotary table is operated by remote control.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Mr.Chen

Phone: +86 15806428103

E-mail: info@ecorinpufoaming.com

Whatsapp:+86 15806428103

Add: Liaoning Road, Beiguan Industrial Park, Jiaozhou, Qingdao Shandong Province